|

| Digital LC Meter |

A LCR meter [Inductance (L), Capacitance (C), and Resistance (R)] is a piece of electronic test equipment used to measure the inductance, capacitance and, resistance of a component. Inductance is the property of an electrical circuit causing voltage to be generated proportional to the rate of change in current in a circuit. In Electronics, capacitance is the ability of a body to hold an electrical charge. Capacitance is also a measure of the amount of electrical energy stored (or separated) for a given electric potential. The electrical resistance of an electrical element measures its opposition to the passage of an electric current. The meter reads L, C and R directly with no human calculation required.

Recently I found this LC meter project on internet and I was looking for that kind of project. Therefore, I build. Amazing it is work! Also the accuracy of this LC meter is great and it is very easy to build. So that, I post it here, because I think it is useful to you. You can visit original post from using this link:

LMC3

The data below were determined based on theoretical calculations, the scale and the display automatically change.

|

Min |

Max |

Resolution |

Accuracy |

| Non Polar Condenser |

1pF |

1nF |

0.1pF |

1% |

|

1nF |

100nF |

1pF |

1% |

|

100nF |

1uF |

1nF |

2.5% |

| Electrolytic Capacitor |

100nF |

100,000uF |

1nF |

5% |

| Inductor |

10nH |

20H |

10nH |

5% |

| Resistance |

1mΩ |

0.5Ω |

1mΩ |

5% |

| Inductance |

0.5Ω |

30Ω |

10mΩ |

10% |

Specifications of the LC Meter

|

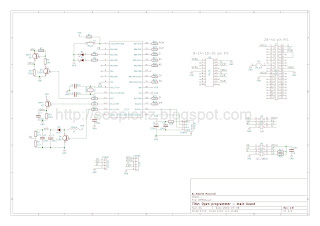

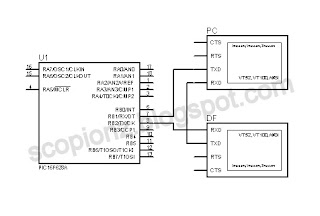

| LC Meter Diagram |

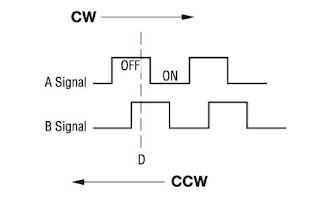

LC Switch:

The purpose of this is, switch between inductance and capacitance mode. When you turn on the LC meter, you should set it to C mode.

Calibration Switch:

You can calibrate LC meter by pressing this. See Calibration for more details.

LC Meter Calibration

You have 3 modes to calibrate. When the process is

completed, calibrated values are saving to the microcontroller’s internal

EEPROM, so of course they are available after the re-start.

C Calibration

- Switch on

- Switch L/C switch to C position

- Leave the test probes freely. Do not even touch it

- Press and hold the CALIB button until the message Switch to meas. Then release the button

- Wait for the appearance of 0.00 pF

L Calibration

- Switch on

- Switch to the L position

- Connect L/C probe and GND probe together

- Press and hold the CALIB button until the message Switch to meas. Then release the button

- Wait for the appearance of 0.00 uH

ESR Calibration

- Switch on

- Switch to the C position

- Connect LE probe and GND probe together

- Press and hold the CALIB button until the message Switch to meas. Then release the button

- Note the value shown on the screen

Calibration Values

- F0 = 499.9k

- Fcal = 355.9k

- Uesr0 = 58.3mV

- Fesr = 83.6k

- Rx = 0mΩ [-5mΩ to 5mΩ]

Critical Components

All the below resistors are 1%.

(In my circuit, I used normal resistors and those are measured using digital multimeter)

- 47Ω - R11

- 47kΩ - R8

- 100kΩ - R3-R5

- 1nF - C8, C11 (Polypropylene or Polyester)

- 33nF - C10 (Polypropylene 275V AC)

- 10uF - C7, C9 (Tantalum)

- 100uH - L1 (Low-loss DC resistance of 0.3-0.4Ω)

Testing

|

| check 22pF ceramic capacitor |

|

| check 100uF electrolytic capacitor |

|

| check 100uH inductor |

I was unable to find a reed relay, so I put 5v ordinary relay temporarily. In addition, my PCB designed for the

TL2285 switches. But, I bought

TL2230 by mistake :)

If the back-light brightness is low, you can increase back-light brightness by decreasing the value of the resistor R2 to 470Ω - 1k. You can change display contrast by adjusting 10k preset.

For PCB, Schematic and hex file, click download button.

You need to discharge capacitors properly before measuring.