The purpose of this post is to provide basic information that one needs to know in order to be able to use microcontrollers successfully in practice. This post, therefore, doesn’t contain any super interesting program or device schematic with amazing solutions. Instead, the following examples are better proof that program writing is neither a privilege nor a talent issue, but the ability of simply putting puzzle pieces together using directives. Rest assured that design and development of devices mainly consists of the ‘test-correct-repeat’ work. Of course, the more you are in it, the more complicated it gets since the puzzle pieces are put together by both children and first-class architects.

Copyright © 1998–2012. MikroElektronika. All rights reserved. All trade and/or services marks mentioned are the property of their respective owners.

4.0 TABLE OF CONTENTS

- 4.1 BASIC CONNECTING

- 4.2 ADDITIONAL COMPONENTS

- 4.3 EXAMPLE 1 - Writing header, configuring I/O pins, using delay function and switch operator

- 4.4 EXAMPLE 2 - Using assembly instructions and internal oscillator LFINTOSC

- 4.5 EXAMPLE 3 - TMR0 as a counter, declaring new variables, enumerated constants, using relay

- 4.6 EXAMPLE 4 - Using timers TMR0, TMR1 and TMR2. Using interrupts, declaring new function

- 4.7 EXAMPLE 5 - Using watch-dog timer

- 4.8 EXAMPLE 6 - Module CCP1 as PWM signal generator

- 4.9 EXAMPLE 7 - Using A/D converter

- 4.10 EXAMPLE 8 - Using EEPROM Memory

- 4.11 EXAMPLE 9 - Two-digit LED counter, multiplexing

- 4.12 EXAMPLE 10 - Using LCD display

- 4.13 EXAMPLE 11 - RS232 serial communication

- 4.14 EXAMPLE 12 - Temperature measurement using DS1820 sensor. Use of 1-wire protocol

- 4.15 EXAMPLE 13 - Sound generation, sound library

- 4.16 EXAMPLE 14 - Using graphic LCD display

- 4.17 EXAMPLE 15 - Using touch panel

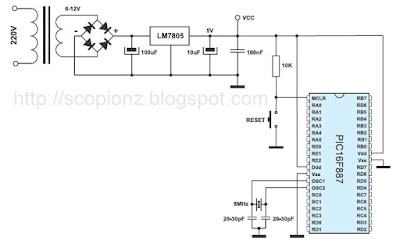

4.1 BASIC CONNECTING

In order to enable the microcontroller to operate properly it is necessary to provide:- Power Supply;

- Reset Signal; and

- Clock Signal.

|

| Basic Connecting |

As seen in figure above, it is about simple circuits, but it does not have to be always like that. If the target device is used for controlling expensive machines or life-support devices, everything gets increasingly complicated! However, this solution is sufficient for the time being...

POWER SUPPLY

Even though the PIC16F887 can operate at different supply voltages, why to test 'Murphy's low'?! A 5V DC power supply is the most suitable. The circuit, shown on the previous page, uses a cheap integrated three-terminal positive regulator LM7805 and provides high-quality voltage stability and quite enough current to enable the microcontroller and peripheral electronics to operate normally (enough here means 1A).RESET SIGNAL

In order that the microcontroller can operate properly, a logic one (VCC) must be applied on the reset pin. The push button connecting the reset pin MCLR to GND is not necessary. However, it is almost always provided because it enables the microcontroller to return safely to normal operating conditions if something goes wrong. By pushing this button, 0V is brought to the pin, the microcontroller is reset and the program execution starts from the beginning. A 10K resistor is used to allow 0V to be applied to the MCLR pin, via the push button, without shorting the 5V DC rail to earth.CLOCK SIGNAL

Even though the microcontroller has a built-in oscillator, it cannot operate without external components which stabilize its operation and determine its frequency (operating speed of the microcontroller). Depending on elements in use as well as their frequencies, the oscillator can be run in four different modes:- LP - Low Power Crystal;

- XT - Crystal / Resonator;

- HS - High speed Crystal / Resonator; and

- RC - Resistor / Capacitor.

|

| Crystal Settings |

Quartz Crystal

When the quartz crystal is used for frequency stabilization, a built-in oscillator operates at a precise frequency which is not affected by changes in temperature and power supply voltage. This frequency is usually labeled on the crystal casing.Apart from the crystal, capacitors C1 and C2 must also be connected as per schematic below. Their capacitance is not of great importance. Therefore, the values provided in the table below should be considered as a recommendation, not as a strict rule.

|

| Crystal settings |

Ceramic Resonator

Ceramic resonator is cheaper, but very similar to quartz by its function and the way of operation. This is why schematics illustrating their connection to the microcontroller are identical. However, the capacitor value is slightly different due to different electric features. Refer to the table below. |

| Resonator settings |

Such resonators are usually connected to oscillators when it is not necessary to provide extremely precise frequency.

RC Oscillator

If the operating frequency is not of importance then there is no need to use additional expensive components for stabilization. Instead, a simple RC network, as shown in figure below, is sufficient. Since only the input of the local oscillator is used here, the clock signal with the Fosc/4 frequency will appear on the OSC2 pin. This frequency also represents the operating frequency of the microcontroller, i.e. the speed of instruction execution. |

| RC Oscillator |

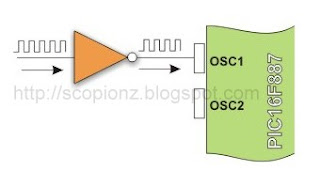

External Oscillator

If it is required to synchronize the operation of several microcontrollers or if for some reason it is not possible to use any of the previous schematics, a clock signal may be generated by an external oscillator. Refer to figure below. |

| External Oscillator |

Regardless of the fact that the microcontroller is a product of modern technology, it is of no use if not connected to additional components. Simply put, the appearance of voltage on the microcontroller pins means nothing if not used for performing certain operations such as to turn something on/off, shift, display etc.

Back to top

4.2 ADDITIONAL COMPONENTS

This section covers the most commonly used additional components in practice such as resistors, transistors, LED diodes, LED displays, LCD displays and RS232 communication circuits.SWITCHES AND PUSH-BUTTONS

Switches and push-buttons are probably the simplest devices providing the simplest way of detecting the appearance of a voltage on a microcontroller input pin. Nevertheless, it is not as simple as it seems... The reason for it is a contact bounce. |

| contact bounce |

The contact bounce is a common problem with mechanical switches. When the contacts strike together, their momentum and elasticity act together to cause bounce. The result is a rapidly pulsed electrical current instead of a clean transition from zero to full current. It mostly occurs due to vibrations, slight rough spots and dirt between contacts. This effect is usually unnoticeable when using these components in everyday life because the bounce happens too fast to affect most equipment. However, it causes problems in some analog and logic circuits that respond fast enough to misinterpret on/off pulses as a data stream. Anyway, the whole process doesn't last long (a few micro or milliseconds), but long enough to be registered by the microcontroller. When only a push-button is used as a counter signal source, errors occur in almost 100% of cases!

This problem may be easily solved by connecting a simple RC circuit to suppress quick voltage changes. Since the bounce period is not defined, the values of components are not precisely determined. In most cases it is recommended to use the values as shown in figure below.

|

| RC circuit |

If complete stability is needed then radical measures should be taken. The output of the circuit, shown in figure below (RS flip-flop), will change its logic state only after detecting the first pulse triggered by a contact bounce. This solution is more expensive (SPDT switch), but the problem is definitely solved.

|

| RS flip-flop |

In addition to these hardware solutions, there is also a simple software solution. When the program tests the logic state of an input pin and detects a change, the check should be done one more time after a certain delay. If the program confirms the change, it means that a switch/push button has changed its position. The advantages of such solution are obvious: it is free of charge, effects of contact bounce are eliminated and it can be applied to the poorer quality contacts as well.

RELAY

A relay is an electrical switch that opens and closes under the control of another electrical circuit. It is therefore connected to output pins of the microcontroller and used to turn on/off high-power devices such as motors, transformers, heaters, bulbs, etc. These devices are almost always placed away from the board's sensitive components. There are various types of relays, but all of them operate in the same way. When current flows through the coil, the relay is operated by an electromagnet to open or close one or more sets of contacts. Similar to optocouplers, there is no galvanic connection (electrical contact) between input and output circuits. Relays usually demand both higher voltage and highercurrent to start operation, but there are also miniature ones that can be activated by low current directly obtained from a microcontroller pin.This figure below shows the most commonly used solution.

|

| Connecting Relay |

In order to prevent the appearance of high voltage self-induction, caused by a sudden stop of the current flow through the coil, an inverted polarized diode is connected in parallel to the coil. The purpose of this diode is to 'cut off' the voltage peak.

LED DIODES

You probably know all you need to know about LED diodes, but you should also think of the younger generations... Let's see, how to destroy an LED?! Well...Easily.Quick Burning

Like any other diode, LEDs have two ends- an anode and a cathode. Connect a diode properly to the power supply voltage and it will happily emit light. Turn the diode upside down and apply the same power supply voltage (even for a moment). It will not emit light - NEVER AGAIN!Slow Burning

There is a nominal, i.e. maximum current limitation specified for every LED which must not be exceeded. If it happens, the diode will emit more intensive light, but just for a short period of time.Something to Remember

Similarly, all you need to do is to discard a current limiting resistor shown below. Depending on the power supply voltage, the effects might be spectacular! |

| Protecting LED Diode |

LED DISPLAY

Basically, an LED display is nothing more than several LEDs molded in the same plastic case. There are many types of displays and some of them are composed of several dozens built-in diodes which can display different symbols. Nevertheless, the most commonly used display is the 7-segment display. It is composed of 8 LEDs. Seven segments of a digit are arranged as a rectangle for symbol displaying, whereas the additional segment is used for the purpose of displaying decimal point. In order to simplify connection, anodes or cathodes of all diodes are connected to the common pin so that there are common anode displays and common cathode displays, respectively. Segments are marked with the letters from a to g, plus dp, as shown in figure below. When connecting, each diode is treated separately, which means that each must have its own current limiting resistor.Here are a few important things that you should pay attention to when buying LED displays:

- As mentioned, depending on whether anodes or cathodes are connected to the common pin, there are common anode displays and common cathode displays. As for their appearance, there is no difference between these displays at all so it is recommended to check carefully prior to installing them which one is used.

- Each microcontroller pin has a maximum current limitation it can receive or give. Thus, if several displays are connected to the microcontroller it is recommended to use the so called Low current LEDs using only 2mA for the operation.

- Display segments are usually marked with the letters from a to g, but there is no fast rule indicating to which display pins they are connected. For this reason it is very important to check connecting prior to commencing writing a program or designing a device.

|

| LED Display Model |

Displays connected to the microcontroller usually occupy a large number of valuable I/O pins, which can be a big problem especially when it is needed to display multi digit numbers. The problem is more than obvious if, for example, it is needed to display two 6-digit numbers (a simple calculation shows that 96 output pins are needed in this case). The solution to this problem is called multiplexing.

Here is how an optical illusion based on the same operating principle as a film camera is made. Only one digit at a time is active, but they change their on/off conditions so quickly making impression that all digits of a number are simultaneously active.

|

| LED Multiplexing |

Here is an explanation on the figure above. First a byte representing units is applied on a microcontroller PORT2 and the transistor T1 is activated at the same time. After a while, the transistor T1 is turned off, a byte representing tens is applied on the PORT2 and the transistor T2 is activated. This process is being cyclically repeated at high speed for all digits and corresponding transistors.

A disappointing fact which indicates that the microcontroller is just a kind of miniature computer designed to understand only the language of zeros and ones is fully expressed when displaying any digit. Namely, the microcontroller does not know what units, tens or hundreds are, nor what ten digits we are used to look like. For this reason, each number to be displayed must go through the following procedure:

First of all, a multi digit number must be split into units, tens etc. in a special subroutine. Then each of these digits must be stored in specific bytes. Digits get recognizable appearance by performing ‘masking’. In other words, the binary format of each digit is replaced by a different combination of bits using a simple subroutine. For example, the digit 8 (0000 1000) is replaced by the binary number 0111 1111 in order to activate all LEDs displaying the digit 8. The only diode remaining inactive here is reserved for the decimal point.

If a microcontroller port is connected to the display in such a way that bit 0 activates segment ‘a’, bit 1 activates segment ‘b’, bit 2 segment ‘c’ etc., then the table below shows the mask for each digit.

|

| Masking |

|

| Mask Table |

In addition to digits from 0 to 9, there are some letters- A, C, E, J, F, U, H, L, b, c, d, o, r, t, that can also be displayed by masking.

In the event that common anode displays are used, all ones contained in the previous table should be replaced by zeros and vice versa. Additionally, PNP transistors should be used as drivers.

OPTOCOUPLER

An optocoupler is a device commonly used to galvanically separate microcontroller electronics from any potentially dangerous current or voltage in its surroundings. Optocouplers usually have one, two or four light sources (LED diodes) on their input while on their output, opposite to diodes, there is the same number of elements sensitive to light (phototransistors, photo-thyristors or photo-triacs). The point is that an optocoupler uses a short optical transmission path to transfer a signal between the elements of circuit, while keeping them electrically isolated. This isolation makes sense only if diodes and photosensitive elements are separately powered. In this way, the microcontroller and expensive additional electronics are completely protected from high voltage and noises which are the most common cause of destroying, damaging or unstable operation of electronic devices in practice. The most frequently used optocouplers are those with phototransistors on their outputs. When it comes to the optocouplers with internal base-to-pin 6 connection (there are also optocouplers without it), the base can be left unconnected. |

| Optocoupler Usage |

The R/C network represented by a broken line in the figure above denotes an optional connection which lessens the effects of noises by eliminating very short pulses.

LCD DISPLAY

This component is specifically manufactured to be used with microcontrollers, which means that it cannot be activated by standard IC circuits. It is used for displaying different messages on a miniature liquid crystal display. The model described here is for its low price and great capabilities most frequently used in practice. It is based on the HD44780 microcontroller (Hitachi) and can display messages in two lines with 16 characters each. It can display all the letters of alphabet, Greek letters, punctuation marks, mathematical symbols etc. It is also possible to display symbols made up by the user. Other useful features include automatic message shift (left and right), cursor appearance, LED backlight etc.LCD Display Pins

Along one side of the small printed board of the LCD display there are pins that enable it to be connected to the microcontroller. There are in total of 14 pins marked with numbers (16 if there is a backlight). Their function is described in the table bellow: |

| LCD Display Pins |

LCD Screen

An LCD screen can display two lines with 16 characters each. Every character consists of 5x8 or 5x11 dot matrix. This book covers a 5x8 character display which is most commonly used. |

| LCD Screen |

Display contrast depends on the power supply voltage and whether messages are displayed in one or two lines. For this reason, varying voltage 0-Vdd is applied to the pin marked as Vee. A trimmer potentiometer is usually used for this purpose. Some of the LCD displays have built-in backlight (blue or green LEDs). When used during operation, a current limiting resistor should be serially connected to one of the pins for backlight power supply (similar to LED diodes).

|

| Connecting LCD |

If there are no characters displayed or if all of them are dimmed when the display is switched on, the first thing that should be done is to check the potentiometer for contrast adjustment. Is it properly adjusted? The same applies if the mode of operation has been changed (writing in one or two lines).

LCD Memory

LCD display contains three memory blocks:- DDRAM Display Data RAM;

- CGRAM Character Generator RAM; and

- CGROM Character Generator ROM.

DDRAM Memory

DDRAM memory is used for storing characters to be displayed. The size of this memory is capable of storing 80 characters. Some memory locations are directly connected to the characters on display.Everything works quite simply: it is enough to configure the display to increment addresses automatically (shift right) and set the starting address for the message to be displayed (for example 00 hex).

Afterwards, all characters sent through lines D0-D7 will be displayed in the message format we are used to- from left to right. In this case, displaying starts from the first field of the first line because the initial address is 00 hex. If more than 16 characters are sent, then all of them will be memorized, but only the first sixteen characters will be visible. In order to display the rest of them, the shift command should be used. Virtually, everything looks as if the LCD display is a window which shifts left-right over memory locations containing different characters. In reality, this is how the effect of the message shifting over the screen has been created.

|

| DDRAM Memory |

If the cursor is on, it appears at the currently addressed location. In other words, when a character appears at the cursor position, it will automatically move to the next addressed location.

This is a sort of RAM memory so that data can be written to and read from it, but its content is irretrievably lost when the power goes off.

CGROM Memory

CGROM memory contains a standard character map with all characters that can be displayed on the screen. Each character is assigned to one memory location: |

| CGROM Memory |

The addresses of CGROM memory locations match the characters of ASCII. If the program being currently executed encounters a command ‘send character P to port’ then the binary value 0101 0000 appears on the port. This value is the ASCII equivalent to the character P. It is then written to an LCD, which results in displaying the symbol from the 0101 0000 location of CGROM. In other words, the character ‘P’ is displayed. This applies to all letters of alphabet (capitals and small), but not to numbers. As seen on the previous map, addresses of all digits are pushed forward by 48 relative to their values (digit 0 address is 48, digit 1 address is 49, digit 2 address is 50 etc.). Accordingly, in order to display digits correctly it is necessary to add the decimal number 48 to each of them prior to being sent to an LCD.

What is ASCII? From their inception till today, computers can recognize only numbers, but not letters. It means that all data a computer swaps with a peripheral device has a binary format even though the same is recognized by the man as letters (the keyboard is an excellent example). In other words, every character matches a unique combination of zeroes and ones. ASCII is character encoding based on the English alphabet. ASCII code specifies a correspondence between standard character symbols and their numerical equivalents.

|

| ASCII codes table |

CGRAM Memory

Apart from standard characters, the LCD display can also display symbols defined by the user itself. It can be any symbol in the size of 5x8 pixels. RAM memory called CGRAM in the size of 64 bytes enables it.Memory registers are 8 bits wide, but only 5 lower bits are used. Logic one (1) in every register represents a dimmed dot, while 8 locations grouped together represent one character. It is best illustrated in figure below:

|

| CGRAM Memory |

Symbols are usually defined at the beginnig of the program by simple writing zeros and ones to registers of CGRAM memory so that they form desired shapes. In order to display them it is sufficient to specify their address. Pay attention to the first coloumn in the CGROM map of characters. It doesn't contain RAM memory addresses, but symbols being discussed here. In this example, ‘display 0’ means - display ‘č’, ‘display 1’ means - display ‘ž’ etc.

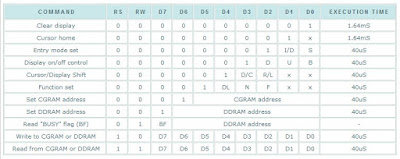

LCD Basic Commands

All data transferred to an LCD through the outputs D0-D7 will be interpreted as a command or a data, which depends on the RS pin logic state:- RS = 1 - Bits D0 - D7 are addresses of the characters to be displayed. LCD processor addresses one character from the character map and displays it. The DDRAM address specifies location on which the character is to be displayed. This address is defined prior to transferring character or the address of the previously transferred character is automatically incremented.

- RS = 0 - Bits D0 - D7 are commands for setting the display mode.

Here is a list of commands recognized by the LCD:

|

| LCD Commands list |

|

| LCD Commands details |

WHAT IS THE BUSY FLAG?

Compared to the microcontroller, the LCD is an extremely slow component. For this reason, it was necessary to provide a signal which would, upon command execution, indicate that the display is ready for the next piece of data. That signal, called the busy flag, can be read from the line D7. The display is ready to receive new data when the voltage on this line is 0V (BF=0).LCD Connecting

Depending on how many lines are used for connecting an LCD to the microcontroller, there are 8-bit and 4-bit LCD modes. The appropriate mode is selected at the beginning of the operation in the process called 'initialization'. The 8-bit LCD mode uses outputs D0- D7 to transfer data as explained on the previous page.The main purpose of the 4-bit LCD mode is to save valuable I/O pins of the microcontroller. Only 4 higher bits (D4-D7) are used for communication, while others may be left unconnected. Each piece of data is sent to the LCD in two steps- four higher bits are sent first (normally through the lines D4-D7), then four lower bits. Initialization enables the LCD to link and interpret received bits correctly.

|

| Connecting LCD to the microcontroller |

Data is rarely read from the LCD (it is mainly transferred from the microcontroller to the LCD) so it is often possible to save an extra I/O pin by simple connecting the R/W pin to the Ground. Such a saving has its price. Messages will be normally displayed, but it will not be possible to read the busy flag since it is not possible to read the display either. Fortunately, there is a simple solution. After sending a character or a command it is important to give the LCD enough time to do its job. Owing to the fact that the execution of a command may last for approximately 1.64mS, it will be sufficient to wait about 2mS for the LCD.

LCD Initialization

The LCD is automatically cleared when powered up. It lasts for approximately 15mS. After this, it is ready for operation. The mode of operation is set by default, which means that:- Display is cleared.

- Mode

DL = 1 - Communication through 8-bit interface

N = 0 - Messages are displayed in one line

F = 0 - Character font 5 x 8 dots - Display/Cursor on/off

D = 0 - Display off

U = 0 - Cursor off

B = 0 - Cursor blink off - Character entry

ID = 1 Displayed addresses are automatically incremented by 1

S = 0 Display shift off

There are two initialization algorithms. Which one is to be performed depends on whether connecting to the microcontroller is through 4 or 8-bit interface. In both cases, all that’s left to do after initialization is to specify basic commands and of course - to display messages.

Refer to figure below for the procedure in 8-bit initialization:

|

| 8-bit initialization |

It is not a mistake! In this algorithm, the same value is transferred three times in a row.

The procedure in 4-bit initialization is as follows:

|

| 4-bit initialization |

Let's do it in mikroC.

function to perform all described operations for LCD initialization. */

...

Lcd_Init(); // Initialize LCD

...

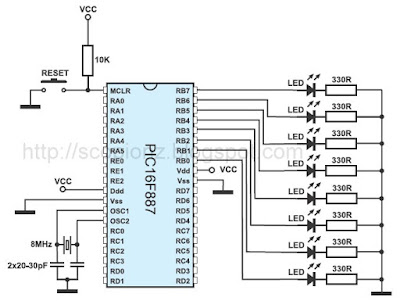

4.3 EXAMPLE 1

Writing header, configuring I/O pins, using delay function and switch operator

The only purpose of this program is to turn on a few LED diodes on port B. Anyway, use this example to study what a real program looks like. Figure below shows connection schematic, while the program is on the next page. |

| Configuring I/O pins |

When switching on, every other LED diode on the port B emits light, which indicates that the microcontroller is properly connected and operates normally.

This example describes a correctly written header. It’s the same for all the programs described in this book. To skip repetitiveness, it will not be written in the following examples, but is considered to be at the beginning of every program and marked as ‘Header’.

|

| Header Example |

To make this example more interesting, we will enable LEDs connected to the port B to blink. There are several ways to do it:

- As soon as the microcontroller is turned on, all LEDs will emit light for a second. The Delay function is in charge of it in the program. It’s only needed to set delay expressed in milliseconds.

- After one second, the program enters the for loop and remains there as long as the variable k is less than 20. The variable is incremented by 1 after each iteration. Within the for loop, the switch operation monitors port B logic state. If PORTB=0xFF, its state is inverted into 0x00 and vice verse. Any change of these logic states causes all LEDs to blink. Duty Cycle is 5:1 (500mS:100mS).

- When the program exits the for loop, the port B logic state changes (0xb 01010101) and the program enters the endless while loop and remains there as long as 1=1. The port B logic state is inverted each 200mS.

|

| Program Example |

4.4 EXAMPLE 2

Using assembly instructions and internal oscillator LFINTOSC

This is actually a sequel to the previous example, but deals with a bit more complicated problem... The idea is to make LED diodes on the port B blink slowly. It can be done by setting large value for delay parameter in the Delay function. But there is also another, more efficient manner to make this happen. You remember that this microcontroller has built-in oscillator LFINTOSC which operates at the frequency of 31kHz? Now, it’s time to ‘give it a chance’.The program starts with the do-while loop and remains there for 20 cycles. After each iteration, 100mS delay is provided, which is reflected as relatively fast LED blinking of the port B. When the program exits this loop, the microcontroller starts using the LFINTOSC oscillator as a clock signal source. The LED blinking is considerably slower now even though the program executes the same do-while loop with 10 times shorter delay.

For the purpose of making some potentionally dangerous situation more obvious here, control bits are activated by assembly instructions. Simply put, when entering or exiting the assembly instruction in the program, the compiler doesn’t save data on currently active RAM bank, which means that in this program section, bank selection depends on the SFR registers in use. When switching back to the program section written in C, the control bits RP0 and RP1 must return the state they had before ‘assembly language adventure’. In this program, the problem is solved by using the saveBank auxiliary variable which saves the state of these two bits.

int k = 0;

char saveBank;

void main() {

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTB = 0; // All port B pins are set to 0

TRISB = 0; // Port B pins are configured as outputs

do {

PORTB = ~PORTB; // Invert port B logic state

Delay_ms(100); // 100mS delay

k++; // Increment k by 1

}

while(k<20); // Remain in loop while k<20

k=0; // Reset variable k

saveBank = STATUS & 0b01100000; // Save the state of bits RP0 and RP1

// (bits 5 and 6 of the STATUS register)

asm { // Start of assembly sequence

bsf STATUS,RP0 // Select memory bank containing the OSCCON

bcf STATUS,RP1 // register

bcf OSCCON,6 // Select internal oscillator LFINTOSC

bcf OSCCON,5 // of 31KHz frequency

bcf OSCCON,4

bsf OSCCON,0 // Microcontroller uses internal oscillator

} // End of assembly sequence

STATUS &= 0b10011111; // Bits RP0 and RP1 return their original state

STATUS |= saveBank;

do {

PORTB = ~PORTB; // Invert port B logic state

Delay_ms(10); // 10 mS delay

k++; // Increment k by 1

}

while(k<20); // Remain in loop while k<20

}

You have noticed that the clock signal source is changed ‘on the fly’. If you want to make sure of it, remove quartz crystal prior to switching the microcontroller on. The microcontroller will not start to operate because the Config Word loaded with the program requires the use of crystal on switching on. If you remove the crystal later during operation, nothing will happen, it will not affect the microcontroller at all.

Back to top

4.5 EXAMPLE 3

TMR0 as a counter, declaring new variables, enumerated constants, using relay

Referring to the previous examples, the microcontroller executes the program without being affected in any way by its surrounding. Practically, devices operating in this manner are very rare (for example, simple neon sign controller). Input pins are also used in this example. There is a schematic in figure below, while the program is on the next page. It’s still very simple. Timer TMR0 is used as a counter. The counter input is connected to a push button so that any button press causes timer TMR0 to count one pulse. When the number of pulses matches the number stored in the TEST register, a logic one (5V) appears on the pin PORTD.3. This voltage activates an electromechanical relay, and this bit is called ‘RELAY’ in the program, therefore.In this example, the TEST register stores number 5. Of course, it can be any number obtained either by computing or defined as a constant. Besides, the microcontroller can activate some other device instead of relay, while the sensor can be used instead of the push button. This example illustrates one of the most common applications of the microcontroller in the industry; when something is performed as many times as needed, then something else should be turned on or off.

|

| TMR0 as a counter |

void main() {

char TEST = 5; // Constant TEST = 5

enum outputs {RELAY = 3}; // Constant RELAY = 3

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTA = 0; // Reset port A

TRISA = 0xFF; // All portA pins are configured as inputs

PORTD = 0; // Reset port D

TRISD = 0b11110111; // Pin RD3 is configured as an output, while the rest are

// configured as inputs

OPTION_REG.F5 = 1; // Counter TMR0 receives pulses through the RA4 pin

OPTION_REG.F3 = 1; // Prescaler rate is 1:1

TMR0 = 0; // Reset timer/counter TMR0

do {

if (TMR0 == TEST) // Does the number in timer match constant TEST?

(PORTD.RELAY = 1); // Numbers match. Set the RD3 bit (output RELAY)

}

while (1); // Remain in endless loop

}

Only one enumerated constant RELAY is used in this example. It is assigned a value when declared.

If several port D pins are connected to relays, the expression above could be written in this way as well:

All the constants, following those with assigned values (RELAY = 3 and MOTOR = 6), are automatically assigned values incremented by 1 relative to the previous constant value. In this example, constants HEATER and PUMP will be assigned values 4 and 7, respectively (HEATER = 4 and PUMP = 7).

Back to top

4.6 EXAMPLE 4

Using timers TMR0, TMR1 and TMR2. Using interrupts, declaring new function

If you have read the previous example, you probably have noticed a disadvantage of providing delays using loops. In all those cases, the microcontroller is ‘captive’ and does nothing. It simply waits for some time to pass. Such waste of time is an unacceptable luxury and some other method should be applied therefore.Do you remember the story about timers? Interrupts? This example makes links between them in a practical way. The schematic is still the same as well as the challenge. It is necessary to provide a delay long enough to notice changes on a port. Timer TMR0 with assigned prescaler is used for this purpose. An interrupt is generated on every timer register overflow and every interrupt routine automatically increments the cnt variable by 1. When it’s value reaches 400, the port B is incremented by 1. The whole procedure is performed ‘behind the scenes’, which enables the microcontroller to do something else.

|

| Example 4 |

unsigned cnt; // Define variable cnt

void interrupt() {

cnt++; // Interrupt causes cnt to be incremented by 1

TMR0 = 96; // Timer TMR0 is returned its initial value

INTCON = 0x20; // Bit T0IE is set, bit T0IF is cleared

}

void main() {

OPTION_REG = 0x84; // Prescaler is assigned to timer TMR0

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

TRISB = 0; // All port B pins are configured as outputs

PORTB = 0x0; // Reset port B

TMR0 = 96; // Timer T0 counts from 96 to 255

INTCON = 0xA0; // Enable interrupt TMR0

cnt = 0; // Variable cnt is assigned a 0

do { // Endless loop

if (cnt == 400) { // Increment port B after 400 interrupts

PORTB = PORTB++; // Increment number on port B by 1

cnt = 0; // Reset variable cnt

}

} while(1);

}

Interrupt occurs on every timer register TMR0 overflow.

unsigned short cnt; // Define variable cnt

void interrupt() {

cnt++ ; // Interrupt causes cnt to be incremented by 1

PIR1.TMR1IF = 0; // Reset bit TMR1IF

TMR1H = 0x80; // TMR1H and TMR1L timer registers are returned

TMR1L = 0x00; // their initial values

}

void main() {

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTB = 0xF0; // Initial value of port B bits

TRISB = 0; // Port B pins are configured as outputs

T1CON = 1; // Set timer TMR1

PIR1.TMR1IF = 0; // Reset bit TMR1IF

TMR1H = 0x80; // Set initial value for timer TMR1

TMR1L = 0x00;

PIE1.TMR1IE = 1; // Enable interrupt on overflow

cnt = 0; // Reset variable cnt

INTCON = 0xC0; // Enable interrupt (bits GIE and PEIE)

do { // Endless loop

if (cnt == 76) { // Change port B state after 76 interrupts

PORTB = ~PORTB; // Number in port B is inverted

cnt = 0; // Reset variable cnt

}

} while (1);

}

In this case, an interrupt is enabled after the timer register TMR1 (TMR1H, TMR1L) overflow occurs. Combination of bits changing on port B is different from that in the previous example.

unsigned short cnt; // Define variable cnt

void Replace() {

PORTB = ~PORTB; // Define new function ‘Replace’

} // Function inverts port state

void interrupt() {

if (PIR1.TMR2IF) { // If bit TMR2IF = 1,

cnt++ ; // Increment variable cnt by 1

PIR1.TMR2IF = 0;// Reset bit and

TMR2 = 0; // reset register TMR2

}

}

// main

void main() {

cnt = 0; // Reset variable cnt

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTB = 0b10101010; // Logic state on port B pins

TRISB = 0; // All port B pins are configured as outputs

T2CON = 0xFF; // Set timer T2

TMR2 = 0; // Initial value of timer register TMR2

PIE1.TMR2IE = 1; // Enable interrupt

INTCON = 0xC0; // Set bits GIE and PEIE

while (1) { // Endless loop

if (cnt > 30) { // Change PORTB after more than 30 interrupts

Replace(); // Function Replace inverts the port B state

cnt = 0; // Reset variable cnt

}

}

}

This time, an interrupt occurs after timer register TMR2 overflow occurs. The Replace function, which normally doesn’t belong to C, is used in this example to invert port pins state.

Back to top

4.7 EXAMPLE 5

Using watch-dog timer

This example illustrates how the watch-dog timer should not be used. A command used for resetting this timer is intentionally left out in the main program loop, thus enabling it to win the time battle and cause the microcontroller to be reset. As a result, the microcontroller will be reset all the time, which is reflected as PORTB LED blinking. |

| Example 5 |

void main() {

OPTION_REG = 0x0E; // Prescaler is assigned to timer WDT (1:64)

asm CLRWDT; // Assembly command to reset WDT timer

PORTB = 0x0F; // Initial value of the PORTB register

TRISB = 0; // All port B pins are configured as outputs

Delay_ms(300); // 30mS delay

PORTB = 0xF0; // Porta B value different from initial

while (1); // Endless loop. Program remains here until WDT

// timer resets the microcontroller

}

In order to make this example work properly, it is necessary to enable the watchdog timer by selecting the Watchdog Timer - Enabled option in mE programmer.

Back to top

4.8 EXAMPLE 6

Module CCP1 as PWM signal generator

This example illustrates the use of CCP1 module in PWM mode. To make things more interesting, the duration of the P1A output pulses (PORTC,2) may be changed using pushbuttons symbolically marked as ‘DARK’ and ‘BRIGHT’, while the set duration is seen as binary combination on port B. The operation of this module is under control of the functions belonging to the specialized PWM Library. Three of them are used here:- PWM1_init has the prototype:

void Pwm1_Init(long freq);

Parameter freq sets the frequency of PWM signal expressed in herz. In this example it amounts to 5kHz. - PWM1_Start has the prototype:

void Pwm1_Start(void); - PWM1_Set_Duty has the prototype:

void Pwm1_Set_Duty(unsigned short duty_ratio);

Parameter duty_ratio sets pulse duration in pulse sequence.

The PWM library also contains the PWM_Stop function used to disable this mode. Its prototype is:

void Pwm1_Stop(void); |

| Example 6 |

unsigned short current_duty, old_duty; // Define variables

// current_duty and old_duty

void initMain() {

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTA = 255; // Port A initial state

TRISA = 255; // All port A pins are configured as inputs

PORTB = 0; // Initial state of port B

TRISB = 0; // All port B pins are configured as outputs

PORTC = 0; // Port C initial state

TRISC = 0; // All port C pins are configured as outputs

PWM1_Init(5000); // PWM module initialization (5KHz)

}

void main() {

initMain();

current_duty = 16; // Initial value of variable current_duty

old_duty = 0; // Reset variable old_duty

PWM1_Start(); // Start PWM1 module

while (1) { // Endless loop

if (Button(&PORTA, 0,1,1)) // If the button connected to RA0 is pressed

current_duty++ ; // increment variable current_duty

if (Button(&PORTA, 1,1,1)) // If the pressed button is connected to RA1

current_duty-- ; // decrement value current_duty

if (old_duty != current_duty) { // If current_duty and old_duty are not

PWM1_Set_Duty(current_duty); // equal set PWM to a new value,

old_duty = current_duty; // save the new value

PORTB = old_duty; // and show it on port B

}

Delay_ms(200); // 200mS delay

}

}

In order to make this example work properly, it is necessary to tick off the following libraries in the Library Manager prior to compiling:

- PWM

- Button

4.9 EXAMPLE 7

Using A/D converter

The PIC16F887 A/D converter is used in this example. Is it necessary to mention that everything is rather simple?! A variable analog signal is applied to the AN2 pin, while the 10-bit result of conversion is shown on ports B and D (8 LSBs on port D and 2 MSBs on port B). GND is used as negative voltage reference Vref-, while positive voltage reference is applied to the AN3 pin. It enables voltage measurement scale to 'stretch and shrink'.In other words, the A/D converter always generates a 10-bit binary result, which means that it detects a total of 1024 voltage levels (210=1024). The difference between two voltage levels is not always the same. The less the difference between Vref+ and Vref-, the less the difference between two of 1024 levels. As seen, the A/D converter is able to detect slight changes in voltage.

|

| Example 7 |

unsigned int temp_res;

void main() {

ANSEL = 0x0C; // Pins AN2 and AN3 are configured as analog

TRISA = 0xFF; // All port A pins are configured as inputs

ANSELH = 0; // Rest of pins is configured as digital

TRISB = 0x3F; // Port B pins RB7 and RB6 are configured as

// outputs

TRISD = 0; // All port D pins are configured as outputs

ADCON1.F4 = 1 ; // Voltage reference is brought to the RA3 pin.

do {

temp_res = ADC_Read(2); // Result of A/D conversion is copied to temp_res

PORTD = temp_res; // 8 LSBs are moved to port D

PORTB = temp_res >> 2; // 2 MSBs are moved to bits RB6 and RB7

} while(1); // Endless loop

}

In order to make this example work properly, it is necessary to tick off the ADC library in the Library Manager prior to compiling:

- ADC

4.10 EXAMPLE 8

Using EEPROM Memory

This example illustrates write to and read from built-in EEPROM memory. The program works as follows. The main loop constantly reads EEPROM memory location at address 5 (decimal). The program then enters an endless loop in which PORTB is incremented and PORTA.2 input state is checked. At the moment of pressing the push button called MEMO, a number stored in PORTB will be saved in EEPROM and directly read and shown on PORTD in binary form. |

| Example 8 |

void main() {

ANSEL = 0; // All I/O pins are configured as digital

ANSELH = 0;

PORTB = 0; // Port B initial value

TRISB = 0; // All port B pins are configured as outputs

PORTD = 0; // Port B initial value

TRISD = 0; // All port D pins are configured as outputs

TRISA = 0xFF; // All port A pins are configured as inputs

PORTD = EEPROM_Read(5); // Read EEPROM memory at address 5

do {

PORTB=PORTB++; // Increment port B by 1

Delay_ms(100); // 100mS delay

if (PORTA.F2){

EEPROM_Write(5,PORTB); // If MEMO is pressed, save PORTB

PORTD = EEPROM_Read(5); // Read written data

do;

while (PORTA.F2); // Remain in this loop as long as the button is

// pressed

}

}

while(1); // Endless loop

}

In order to check this circuit, it is sufficient to press the MEMO button and turn off the device. After restarting the device, the program will display the saved value on port D. Remember that at the moment of writing, this value was displayed on port B).

In order to make this example work properly, it is necessary to tick off the EEPROM library in the Library Manager prior to compiling:

- EEPROM

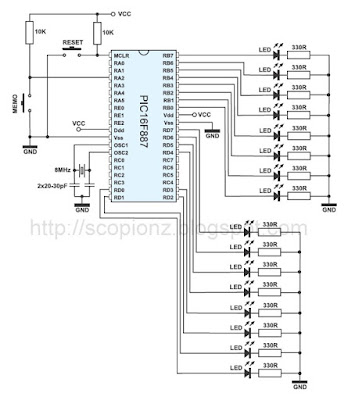

4.11 EXAMPLE 9

Two-digit LED counter, multiplexing

The microcontroller operates as a two-digit counter here. The variable i is incremented (slow enough to be visible) and its value is displayed on a two-digit LED display (99-0). The challenge is to enable a binary number to be converted in decimal and split it in two digits (tens and ones). Since the LED display segments are connected in parallel, it is necessary to ensure that they change fast in order to make impression of simultaneous light emission (time-division multiplexing).In this example, timer TMR0 is in charge of the time-division multiplexing, while the mask function converts a binary number into decimal format.

|

| Example 9 |

unsigned short mask(unsigned short num);

unsigned short digit_no, digit10, digit1, digit, i;

void interrupt() {

if (digit_no==0) {

PORTA = 0; // Turn off both displays

PORTD = digit1; // Set mask for displaying ones on PORTD

PORTA = 1; // Turn on display for ones (LSD)

digit_no = 1;

} else {

PORTA = 0; // Turn off both displays

PORTD = digit10; // Set mask for displaying tens on PORTD

PORTA = 2; // Turn on display for tens (MSD)

digit_no = 0;

}

TMR0 = 0; // Reset counter TMRO

INTCON = 0x20; // Bit T0IF=0, T0IE=1

}

void main() {

OPTION_REG = 0x80; // Set timer TMR0

TMR0 = 0;

INTCON = 0xA0; // Disable interrupt PEIE,INTE,RBIE,T0IE

PORTA = 0; // Turn off both displays

TRISA = 0; // All port A pins are configured as outputs

PORTD = 0; // Turn off all display segments

TRISD = 0; // All port D pins are configured as outputs

do {

for (i = 0; i<=99; i++) { // Count from 0 to 99

digit = i % 10u;

digit1 = mask(digit); // Prepare mask for displaying ones

digit = (char)(i / 10u) % 10u;

digit10 = mask(digit); // Prepare mask for displaying tens

Delay_ms(1000);

}

} while (1); // Endless loop

}

/*Mask *****************************************************/

unsigned short mask(unsigned short num) {

switch (num) {

case 0 : return 0x3F;

case 1 : return 0x06;

case 2 : return 0x5B;

case 3 : return 0x4F;

case 4 : return 0x66;

case 5 : return 0x6D;

case 6 : return 0x7D;

case 7 : return 0x07;

case 8 : return 0x7F;

case 9 : return 0x6F;

}

}

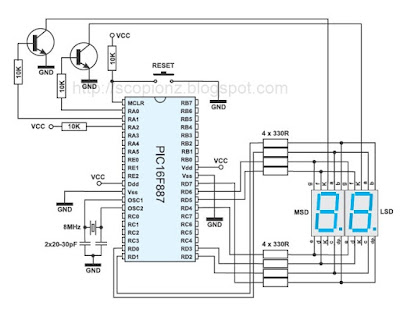

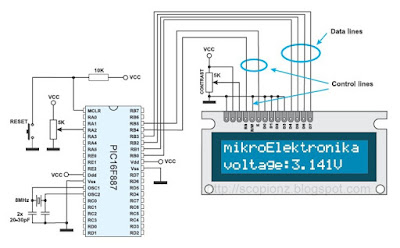

4.12 EXAMPLE 10

Using LCD display

This example illustrates the use of an alphanumeric LCD display. The function libraries simplify this program, which means that the effort made to create software pays off in the end.A message written in two lines appears on the display:

mikroElektronika

LCD example

Two seconds later, the message in the second line is changed and displays voltage present on the A/D converter input (the RA2 pin). For example:

mikroElektronika

voltage:3.141V

In true device, the current temperature or some other measured value can be displayed instead of voltage.

|

| Example 10 |

In order to make this example work properly, it is necessary to tick the following libraries in the Library Manager prior to compiling:

- ADC

- LCD

// LCD module connections

sbit LCD_RS at RB4_bit;

sbit LCD_EN at RB5_bit;

sbit LCD_D4 at RB0_bit;

sbit LCD_D5 at RB1_bit;

sbit LCD_D6 at RB2_bit;

sbit LCD_D7 at RB3_bit;

sbit LCD_RS_Direction at TRISB4_bit;

sbit LCD_EN_Direction at TRISB5_bit;

sbit LCD_D4_Direction at TRISB0_bit;

sbit LCD_D5_Direction at TRISB1_bit;

sbit LCD_D6_Direction at TRISB2_bit;

sbit LCD_D7_Direction at TRISB3_bit;

// End LCD module connections

unsigned char ch; //

unsigned int adc_rd; // Declare variables

char *text; //

long tlong; //

void main() {

INTCON = 0; // All interrupts disabled

ANSEL = 0x04; // Pin RA2 is configured as an analog input

TRISA = 0x04;

ANSELH = 0; // Rest of pins are configured as digital

Lcd_Init(); // LCD display initialization

Lcd_Cmd(_LCD_CURSOR_OFF); // LCD command (cursor off)

Lcd_Cmd(_LCD_CLEAR); // LCD command (clear LCD)

text = "mikroElektronika"; // Define the first message

Lcd_Out(1,1,text); // Write the first message in the first line

text = "LCD example"; // Define the second message

Lcd_Out(2,1,text); // Define the first message

ADCON1 = 0x82; // A/D voltage reference is VCC

TRISA = 0xFF; // All port A pins are configured as inputs

Delay_ms(2000);

text = "voltage:"; // Define the third message

while (1) {

adc_rd = ADC_Read(2); // A/D conversion. Pin RA2 is an input.

Lcd_Out(2,1,text); // Write result in the second line

tlong = (long)adc_rd * 5000; // Convert the result in millivolts

tlong = tlong / 1023; // 0..1023 -> 0-5000mV

ch = tlong / 1000; // Extract volts (thousands of millivolts)

// from result

Lcd_Chr(2,9,48+ch); // Write result in ASCII format

Lcd_Chr_CP('.');

ch = (tlong / 100) % 10; // Extract hundreds of millivolts

Lcd_Chr_CP(48+ch); // Write result in ASCII format

ch = (tlong / 10) % 10; // Extract tens of millivolts

Lcd_Chr_CP(48+ch); // Write result in ASCII format

ch = tlong % 10; // Extract digits for millivolts

Lcd_Chr_CP(48+ch); // Write result in ASCII format

Lcd_Chr_CP('V');

Delay_ms(1);

}

}

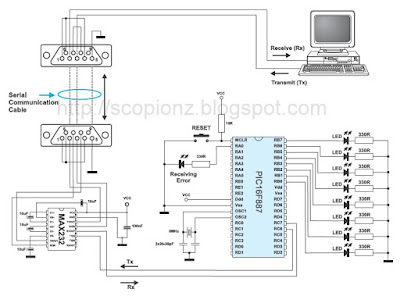

4.13 EXAMPLE 11

RS232 serial communication

This example illustrates the use of the microcontroller’s EUSART module. Connection to a PC is enabled through the RS232 standard. The program works in the following manner. Every byte received via serial communication is displayed using LED diodes connected to port B and is automatically returned to the transmitter after that. If an error occurs on receive, it will be signalled by switching the LED diode on. The easiest way to test the device operation practically is by using a standard Windows program called Hyper Terminal. |

| Example 11 |

unsigned short i;

void main() {

UART1_Init(19200); // Initialize USART module

// (8 bit, 19200 baud rate, no parity bit)

while (1) {

if (UART1_Data_Ready()) { // If data has been received

i = UART1_Read(); // read it

UART1_Write(i); // and send it back

}

}

}

In order to make this example work properly, it is necessary to tick the UART library in the Library Manager prior to compiling:

- UART

4.14 EXAMPLE 12

Temperature measurement using DS1820 sensor. Use of '1-wire' protocol

Temperature measurement is one of the most common tasks performed by the microcontroller. A DS1820 sensor is used for measurement here. It is capable of measuring temperature in the range of -55 °C to 125 °C with 0.5 °C accuracy. For the purpose of transferring data to the microcontroller, a special type of serial communication called 1-wire is used. |

| Example 12 |

Due to a simple and wide use of these sensors, commands used to run and control them are in the form of functions stored in the One_Wire library. There are three functions in total:

- Ow_Reset is used for reseting sensor;

- Ow_Read is used for receiving data from sensor; and

- Ow_Write is used for sending commands to sensor.

This example implies the advantage in using libraries with ready-to-use functions. Concretely, you don’t have to study documentation provided by the manufacturer in order to use this sensor. It is sufficient to copy some of these functions in the program. If you want to know how any of them is declared, just right click on it and select the Help option.

// LCD module connections

sbit LCD_RS at RB4_bit;

sbit LCD_EN at RB5_bit;

sbit LCD_D4 at RB0_bit;

sbit LCD_D5 at RB1_bit;

sbit LCD_D6 at RB2_bit;

sbit LCD_D7 at RB3_bit;

sbit LCD_RS_Direction at TRISB4_bit;

sbit LCD_EN_Direction at TRISB5_bit;

sbit LCD_D4_Direction at TRISB0_bit;

sbit LCD_D5_Direction at TRISB1_bit;

sbit LCD_D6_Direction at TRISB2_bit;

sbit LCD_D7_Direction at TRISB3_bit;

// End LCD module connections

const unsigned short TEMP_RESOLUTION = 9;

char *text = "000.0000";

unsigned temp;

void Display_Temperature(unsigned int temp2write) {

const unsigned short RES_SHIFT = TEMP_RESOLUTION - 8;

char temp_whole;

unsigned int temp_fraction;

// check if temperature is negative

if (temp2write & 0x8000) {

text[0] = '-';

temp2write = ~temp2write + 1;

}

// extract temp_whole

temp_whole = temp2write >> RES_SHIFT ;

// convert temp_whole to characters

if (temp_whole/100)

text[0] = temp_whole/100 + 48;

else

text[0] = '0';

text[1] = (temp_whole/10)%10 + 48; // Extract tens digit

text[2] = temp_whole%10 + 48; // Extract ones digit

// extract temp_fraction and convert it to unsigned int

temp_fraction = temp2write << (4-RES_SHIFT);

temp_fraction &= 0x000F;

temp_fraction *= 625;

// convert temp_fraction to characters

text[4] = temp_fraction/1000 + 48; // Extract thousands digit

text[5] = (temp_fraction/100)%10 + 48; // Extract hundreds digit

text[6] = (temp_fraction/10)%10 + 48; // Extract tens digit

text[7] = temp_fraction%10 + 48; // Extract ones digit

// Display temperature on LCD

Lcd_Out(2, 5, text);

}

void main() {

ANSEL = 0; // Configure AN pins as digital I/O

ANSELH = 0;

C1ON_bit = 0; // Disable comparators

C2ON_bit = 0;

Lcd_Init(); // Initialize LCD

Lcd_Cmd(_LCD_CLEAR); // Clear LCD

Lcd_Cmd(_LCD_CURSOR_OFF); // Turn the cursor off

Lcd_Out(1, 1, " Temperature: ");

// Print degree character, 'C' for Centigrades

Lcd_Chr(2,13,223); // different LCD displays have different char code for degree

// if you see greek alpha letter try typing 178 instead of 223

Lcd_Chr(2,14,'C');

//--- main loop

do {

//--- perform temperature reading

Ow_Reset(&PORTE, 2); // Onewire reset signal

Ow_Write(&PORTE, 2, 0xCC); // Issue command SKIP_ROM

Ow_Write(&PORTE, 2, 0x44); // Issue command CONVERT_T

Delay_us(120);

Ow_Reset(&PORTE, 2);

Ow_Write(&PORTE, 2, 0xCC); // Issue command SKIP_ROM

Ow_Write(&PORTE, 2, 0xBE); // Issue command READ_SCRATCHPAD

temp = Ow_Read(&PORTE, 2);

temp = (Ow_Read(&PORTE, 2) << 8) + temp;

//--- Format and display result on Lcd

Display_Temperature(temp);

Delay_ms(500);

} while (1);

}

In order to make this example work properly, it is necessary to tick the following libraries in the Library Manager prior to compiling:

- One_Wire

- LCD

4.15 EXAMPLE 13

Sound generation, sound library

Audio signals are often used when it is necessary to call the user’s attention, confirm that some of the push buttons is pressed, warn that minimum or maximum values are reached etc. It can be just a ‘beep’ signal as well as longer or shorter melody. This example demonstrates sound generation using functions belonging to the Sound library. |

| Example 13 |

In adition to these functions, the Button function belonging to the same library is used for testing push buttons.

void Tone1() {

Sound_Play(659, 250); // Frequency = 659Hz, duration = 250ms

}

void Tone2() {

Sound_Play(698, 250); // Frequency = 698Hz, duration = 250ms

}

void Tone3() {

Sound_Play(784, 250); // Frequency = 784Hz, duration = 250ms

}

void Melody1() { // Make funny melody 1

Tone1(); Tone2(); Tone3(); Tone3();

Tone1(); Tone2(); Tone3(); Tone3();

Tone1(); Tone2(); Tone3();

Tone1(); Tone2(); Tone3(); Tone3();

Tone1(); Tone2(); Tone3();

Tone3(); Tone3(); Tone2(); Tone2(); Tone1();

}

void ToneA() { // Tone A

Sound_Play(880, 50);

}

void ToneC() { // Tone C

Sound_Play(1046, 50);

}

void ToneE() { // Tone E

Sound_Play(1318, 50);

}

void Melody2() { // Make funny melody 2

unsigned short i;

for (i = 9; i > 0; i--) {

ToneA(); ToneC(); ToneE();

}

}

void main() {

ANSEL = 0; // All I/O pins are digital

ANSELH = 0;

TRISB = 0xF0; // Pins RB7-RB4 are configured as inputs,

// RB3 is configured as an output

Sound_Init(&PORTB, 3);

Sound_Play(1000, 500);

while (1) {

if (Button(&PORTB,7,1,1)) // RB7 generates Tone1

Tone1();

while (PORTB & 0x80) ; // Wait for push button release

if (Button(&PORTB,6,1,1)) // RB6 generates Tone2

Tone2();

while (PORTB & 0x40) ; // Wait for push button release

if (Button(&PORTB,5,1,1)) // RB5 generates melody 2

Melody2();

while (PORTB & 0x20) ; // Wait for push button release

if (Button(&PORTB,4,1,1)) // RB4 generates melody 1

Melody1();

while (PORTB & 0x10) ; // Wait for push button release

}

}

In order to make this example work properly, it is necessary to tick the following libraries in the Library Manager prior to compiling:

- Button

- Sound

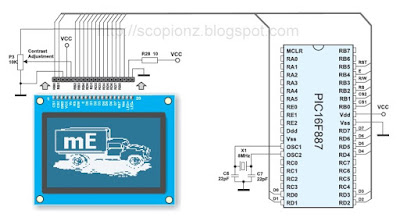

4.16 EXAMPLE 14

Using graphic LCD display

A graphic LCD (GLCD) provides an advanced method for displaying visual messages. While the character LCD can display only alphanumeric characters, the GLCD can display messages in the form of drawings and bitmaps. The most commonly used graphic LCD has 128x64 pixels screen resolution. The GLCD contrast can be adjusted using the potentiometer P1.Here, the GLCD displays a picture of truck the bitmap of which is stored in the

truck_bmp.c file.

|

| Example 14 |

//Declarations------------------------------------------------------------------

const code char truck_bmp[1024];

//--------------------------------------------------------------end-declarations

// Glcd module connections

char GLCD_DataPort at PORTD;

sbit GLCD_CS1 at RB0_bit;

sbit GLCD_CS2 at RB1_bit;

sbit GLCD_RS at RB2_bit;

sbit GLCD_RW at RB3_bit;

sbit GLCD_EN at RB4_bit;

sbit GLCD_RST at RB5_bit;

sbit GLCD_CS1_Direction at TRISB0_bit;

sbit GLCD_CS2_Direction at TRISB1_bit;

sbit GLCD_RS_Direction at TRISB2_bit;

sbit GLCD_RW_Direction at TRISB3_bit;

sbit GLCD_EN_Direction at TRISB4_bit;

sbit GLCD_RST_Direction at TRISB5_bit;

// End Glcd module connections

void delay2S(){ // 2 second delay function

Delay_ms(2000);

}

void main() {

unsigned short ii;

char *someText;

#define COMPLETE_EXAMPLE

ANSEL = 0; // Configure AN pins as digital

ANSELH = 0;

C1ON_bit = 0; // Disable comparators

C2ON_bit = 0;

Glcd_Init(); // Initialize GLCD

Glcd_Fill(0x00); // Clear GLCD

while(1) {

#ifdef COMPLETE_EXAMPLE

Glcd_Image(truck_bmp); // Draw image

delay2S(); delay2S();

#endif

Glcd_Fill(0x00); // Clear GLCD

Glcd_Box(62,40,124,56,1); // Draw box

Glcd_Rectangle(5,5,84,35,1); // Draw rectangle

Glcd_Line(0, 0, 127, 63, 1); // Draw line

delay2S();

for(ii = 5; ii < 60; ii+=5 ){ // Draw horizontal and vertical lines

Delay_ms(250);

Glcd_V_Line(2, 54, ii, 1);

Glcd_H_Line(2, 120, ii, 1);

}

delay2S();

Glcd_Fill(0x00); // Clear GLCD

#ifdef COMPLETE_EXAMPLE

Glcd_Set_Font(Character8x7, 8, 7, 32); // Choose font, see __Lib_GLCDFonts.c

// in Uses folder

#endif

Glcd_Write_Text("mikroE", 1, 7, 2); // Write string

for (ii = 1; ii <= 10; ii++) // Draw circles

Glcd_Circle(63,32, 3*ii, 1);

delay2S();

Glcd_Box(12,20, 70,57, 2); // Draw box

delay2S();

#ifdef COMPLETE_EXAMPLE

Glcd_Fill(0xFF); // Fill GLCD

Glcd_Set_Font(Character8x7, 8, 7, 32); // Change font

someText = "8x7 Font";

Glcd_Write_Text(someText, 5, 0, 2); // Write string

delay2S();

Glcd_Set_Font(System3x5, 3, 5, 32); // Change font

someText = "3X5 CAPITALS ONLY";

Glcd_Write_Text(someText, 60, 2, 2); // Write string

delay2S();

Glcd_Set_Font(font5x7, 5, 7, 32); // Change font

someText = "5x7 Font";

Glcd_Write_Text(someText, 5, 4, 2); // Write string

delay2S();

Glcd_Set_Font(FontSystem5x7_v2, 5, 7, 32); // Change font

someText = "5x7 Font (v2)";

Glcd_Write_Text(someText, 5, 6, 2); // Write string

delay2S();

#endif

}

}

truck_bmp.c file:

// GLCD Picture name: truck.bmp

// GLCD Model: KS0108 128x64

// ------------------------------------------------------

unsigned char const truck_bmp[1024] = {

0, 0, 0, 0, 0,248, 8, 8, 8, 8, 8, 8, 12, 12, 12, 12,

12, 10, 10, 10, 10, 10, 10, 9, 9, 9, 9, 9, 9, 9, 9, 9,

9, 9, 9, 9, 9, 9, 9, 9, 9, 9,137,137,137,137,137,137,

137,137,137,137,137,137,137, 9, 9, 9, 9, 9, 9, 9, 9, 9,

9, 9, 13,253, 13,195, 6,252, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0,255, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

240,240,240,240,240,224,224,240,240,240,240,240,224,192,192,224,

240,240,240,240,240,224,192, 0, 0, 0,255,255,255,255,255,195,

195,195,195,195,195,195, 3, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0,255,240, 79,224,255, 96, 96, 96, 32, 32, 32, 32, 32,

32, 32, 32, 32, 32, 32, 32, 32, 64, 64, 64, 64,128, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0,255, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

255,255,255,255,255, 0, 0, 0, 0,255,255,255,255,255, 0, 0,

0, 0,255,255,255,255,255, 0, 0, 0,255,255,255,255,255,129,

129,129,129,129,129,129,128, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0,255, 1,248, 8, 8, 8, 8, 8, 8, 8, 8, 8, 8,

8, 8, 8, 8, 16,224, 24, 36,196, 70,130,130,133,217,102,112,

160,192, 96, 96, 32, 32,160,160,224,224,192, 64, 64,128,128,192,

64,128, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 63, 96, 96, 96,224, 96, 96, 96, 96, 96, 96,

99, 99, 99, 99, 99, 96, 96, 96, 96, 99, 99, 99, 99, 99, 96, 96,

96, 96, 99, 99, 99, 99, 99, 96, 96, 96, 99, 99, 99, 99, 99, 99,

99, 99, 99, 99, 99, 99, 99, 96, 96, 96, 96, 96, 96, 96, 64, 64,

64,224,224,255,246, 1, 14, 6, 6, 2, 2, 2, 2, 2, 2, 2,

2, 2, 2, 2,130, 67,114, 62, 35, 16, 16, 0, 7, 3, 3, 2,

4, 4, 4, 4, 4, 4, 4, 28, 16, 16, 16, 17, 17, 9, 9, 41,

112, 32, 67, 5,240,126,174,128, 56, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 1, 1, 1, 1, 1, 1,

1, 1,127,127,127,127,255,255,247,251,123,191, 95, 93,125,189,

189, 63, 93, 89,177,115,243,229,207, 27, 63,119,255,207,191,255,

255,255,255,255,255,255,255,127,127,127,127,127,127,127,127,255,

255,255,127,127,125,120,120,120,120,120,248,120,120,120,120,120,

120,248,248,232,143, 0, 0, 0, 0, 0, 0, 0, 0,128,240,248,

120,188,220, 92,252, 28, 28, 60, 92, 92, 60,120,248,248, 96,192,

143,168,216,136, 49, 68, 72, 50,160, 96, 0, 0, 0, 0, 0, 0,

0, 0, 0,128,192,248,248,248,248,252,254,254,254,254,254,254,

254,254,254,254,254,255,255,255,255,255,246,239,208,246,174,173,

169,128,209,208,224,247,249,255,255,252,220,240,127,255,223,255,

255,255,255,255,255,254,254,255,255,255,255,255,255,255,254,255,

255,255,255,255,255,255,254,254,254,254,254,254,254,254,254,254,

254,254,254,254,255,255,255,255,255,255,254,255,190,255,255,253,

240,239,221,223,254,168,136,170,196,208,228,230,248,127,126,156,

223,226,242,242,242,242,242,177, 32, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 1, 1, 1, 1, 3, 3, 3, 7, 7, 7, 7, 7, 15,

15, 15, 7, 15, 15, 15, 7, 7, 15, 14, 15, 13, 15, 47, 43, 43,

43, 43, 43, 47,111,239,255,253,253,255,254,255,255,255,255,255,

191,191,239,239,239,191,255,191,255,255,255,255,255,255,255,255,

255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,255,

255,255,255,255,127,127,127,127,255,255,191,191,191,191,255,254,

255,253,255,255,255,251,255,255,255,127,125, 63, 31, 31, 31, 31,

31, 31, 63, 15, 15, 7, 7, 3, 3, 3, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 1, 0,

1, 1, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 1, 1, 1, 1,

1, 1, 1, 1, 3, 3, 3, 11, 11, 11, 11, 7, 3, 14, 6, 6,

6, 2, 18, 19, 19, 3, 23, 21, 21, 17, 1, 19, 19, 3, 6, 6,

14, 15, 15, 7, 15, 15, 15, 11, 2, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0

};

In order to make this example work properly, it is necessary to tick off the GLCD library in the Library Manager prior to compiling. Also, it is necessary to include document truck_bmp.c into the project.

In order to make this example work properly, it is necessary to tick the GLCD library in the Library Manager prior to compiling. Also, it is necessary to include document truck_bmp.c into the project.

Back to top

4.17 EXAMPLE 15

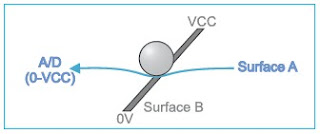

Using touch panel

A touch panel is a thin, self-adhesive transparent panel placed over the screen of a graphic LCD. It is very sensitive to pressure so that even a soft touch causes some changes on output signal. There are a few types of touch panel. The simplest one is the resistive touch panel. |

| Example 15 |

It consists of two transparent rigid foils, forming a ‘sandwich’ structure, that have resistive layers on their inner sides. The resistance of these layers usually does not exceed 1K. The opposite sides of the foils have contacts available for use through a flat cable.

|

| Touch Panel Overview |

The process of determining coordinates of the point in which the touch panel is pressed can be broken up into two steps. The first one is the determination of the X coordinate and the second one is the determination of the Y coordinate of the point.

In order to determine the X coordinate, it is necessary to connect the left contact on the surface A to ground and the right contact to the power supply. This enables a voltage divider to be obtained by pressing the touch panel. The value of the divider is read on the bottom contact of the surface B. Voltage can be in the range of 0V to the power supply and depends on the X coordinate. If the point is closer to the left contact of the surface A, the voltage will be closer to 0V.

|

| Determine coordinates |

In order to determine the Y coordinate, it is necessary to connect the bottom contact on the surface B to ground, and the upper contact to power supply. In this case, the voltage is read on the left contact of the surface A.

In order to determine the X coordinate, it is necessary to connect the left contact on the surface A to ground and the right contact to the power supply. This enables a voltage divider to be obtained by pressing the touch panel. The value of the divider is read on the bottom contact of the surface B. Voltage can be in the range of 0V to the power supply and depends on the X coordinate. If the point is closer to the left contact of the surface A, the voltage will be closer to 0V.

In order to connect a touch panel to the microcontroller it is necessary to create a circuit for touch panel control. By means of this circuit, the microcontroller connects appropriate contacts of the touch panel to ground and the power supply (as described above) in order to determine the X and Y coordinates. The bottom contact of the surface B and left contact of the surface A are connected to the microcontroller’s A/D converter. The X and Y coordinates are determined by measuring voltage on these contacts, respectively. The software consists of writing a menu on graphic LCD, turning the circuit for touch panel control on/off (driving touch panel) and reading the values of A/D converter which actually represent the X and Y coordinates of the point.

Once the coordinates are determined, it is possible to decide what we want the microcontroller to do. In this example, microcontroller turns on/off two digital pins, connected to LED diodes A and B.

This example use functions belonging to the Glcd and ADC library.

Considering that the touch panel surface is slightly larger than the surface of the graphic LCD, in case you want greater accuracy when determining the coordinates, it is necessary to perform the software calibration of the touch panel.

const char msg2[] = "MIKROELEKTRONIKA";

const char msg3[] = "BUTTON1";

const char msg4[] = "BUTTON2";

const char msg5[] = "RC6 OFF";

const char msg6[] = "RC7 OFF";

const char msg7[] = "RC6 ON ";

const char msg8[] = "RC7 ON ";

long x_coord, y_coord, x_coord128, y_coord64; // scaled x-y position

char msg[16];

char * CopyConst2Ram(char * dest, const char * src){

for(;*dest++ = *src++;)

;

return dest;

}

// Glcd module connections

char GLCD_DataPort at PORTD;

sbit GLCD_CS1 at RB0_bit;

sbit GLCD_CS2 at RB1_bit;

sbit GLCD_RS at RB2_bit;

sbit GLCD_RW at RB3_bit;

sbit GLCD_EN at RB4_bit;

sbit GLCD_RST at RB5_bit;

sbit GLCD_CS1_Direction at TRISB0_bit;

sbit GLCD_CS2_Direction at TRISB1_bit;

sbit GLCD_RS_Direction at TRISB2_bit;

sbit GLCD_RW_Direction at TRISB3_bit;

sbit GLCD_EN_Direction at TRISB4_bit;

sbit GLCD_RST_Direction at TRISB5_bit;

// End Glcd module connections

unsigned int GetX() {

//reading X

PORTC.F0 = 1; // DRIVEA = 1 (LEFT drive on, RIGHT drive on

// , TOP drive off )

PORTC.F1 = 0; // DRIVEB = 0 (BOTTOM drive off )

Delay_ms(5);

return ADC_read(0); // reading X value from RA0 (BOTTOM)

}

unsigned int GetY() {

//reading Y

PORTC.F0 = 0; // DRIVEA = 0 (LEFT drive off , RIGHT drive off

// , TOP drive on)

PORTC.F1 = 1; // DRIVEB = 1 (BOTTOM drive on)

Delay_ms(5);

return ADC_read(1); // reading Y value from RA1 (from LEFT)

}

void main() {

PORTA = 0x00;

TRISA = 0x03; // RA0 i RA1 are analog inputs

ANSEL = 0x03;

ANSELH = 0; // Configure other AN pins as digital I/O

PORTC = 0 ;

TRISC = 0 ; // PORTC is output

Glcd_Init(); // Glcd_Init_EP5

Glcd_Set_Font(FontSystem5x7_v2, 5, 7, 32); // Choose font size 5x7

Glcd_Fill(0); // Clear GLCD

CopyConst2Ram(msg,msg1); // Copy "TOUCHPANEL EXAMPLE" string to RAM

Glcd_Write_Text(msg,10,0,1);

CopyConst2Ram(msg,msg2); // Copy "MIKROELEKTRONIKA" string to RAM

Glcd_Write_Text(msg,17,7,1);

//Display Buttons on GLCD:

Glcd_Rectangle(8,16,60,48,1);

Glcd_Rectangle(68,16,120,48,1);

Glcd_Box(10,18,58,46,1);

Glcd_Box(70,18,118,46,1);

CopyConst2Ram(msg,msg3); // Copy "BUTTON1" string to RAM

Glcd_Write_Text(msg,14,3,0);

CopyConst2Ram(msg,msg5); // Copy "RC6 OFF" string to RAM

Glcd_Write_Text(msg,14,4,0);

CopyConst2Ram(msg,msg4); // Copy "BUTTON2" string to RAM

Glcd_Write_Text(msg,74,3,0);

CopyConst2Ram(msg,msg6); // Copy "RC7 OFF" string to RAM

Glcd_Write_Text(msg,74,4,0);

while (1) {

// read X-Y and convert it to 128x64 space

x_coord = GetX();

y_coord = GetY();

x_coord128 = (x_coord * 128) / 1024;

y_coord64 = 64 -((y_coord *64) / 1024);

//if BUTTON1 is selected

if ((x_coord128 >= 10) && (x_coord128 <= 58) && (y_coord64 >= 18) && (y_coord64 <= 46)) {

if(PORTC.F6 == 0) {

PORTC.F6 = 1;

CopyConst2Ram(msg,msg7); // Copy "RC6 ON " string to RAM

Glcd_Write_Text(msg,14,4,0);

}

else {

PORTC.F6 = 0;

CopyConst2Ram(msg,msg5); // Copy "RC6 OFF" string to RAM

Glcd_Write_Text(msg,14,4,0);

}

}

//if BUTTON2 is selected

if ((x_coord128 >= 70) && (x_coord128 <= 118) && (y_coord64 >= 18) && (y_coord64 <= 46)) {

if(PORTC.F7 == 0) {

PORTC.F7 = 1;

CopyConst2Ram(msg,msg8); // Copy "RC7 ON " string to RAM

Glcd_Write_Text(msg,74,4,0);

}

else {

PORTC.F7 = 0;

CopyConst2Ram(msg,msg6); // Copy "RC7 OFF" string to RAM

Glcd_Write_Text(msg,74,4,0);

}

}

Delay_ms(100);

}

}

In order to make this example work properly, it is necessary to tick the following libraries in the Library Manager prior to compiling:

- GLCD

- ADC

- C_Stdlib